燃气真空热水锅炉(Gas vacuum hot water boiler)

燃气真空热水锅炉:就是在封闭的锅炉炉体内部形成一个负压的真空环境,在机体内填充热媒水,以天燃气为燃料,通过燃气燃烧器在炉膛内燃烧加热热媒水,再由热媒水蒸发—冷凝至换热器上,再由换热器来加热需要加热的水称之为燃气真空热水锅炉。

Gas vacuum hot water boiler: It is a vacuum environment that forms a negative pressure inside the closed boiler body, fills the body with heat medium water, uses natural gas as fuel, burns and heats the heat medium water in the furnace through a gas burner, evaporates and condenses the heat medium water to the heat exchanger, and then heats the water that needs to be heated by the heat exchanger. It is called a gas vacuum hot water boiler.

燃气真空热水锅炉的工作原理:利用水在低压情况下沸点低的特性,快速加热封密的炉体内填装的热媒水,使热媒水沸腾蒸发出高温水蒸汽,水蒸汽凝结在换热管上加热换热管内的冷水,达到供应热水的目的。

The working principle of a gas vacuum hot water boiler: By utilizing the low boiling point of water under low pressure, the hot medium water filled in the sealed furnace is quickly heated, causing the hot medium water to boil and evaporate into high-temperature water vapor. The water vapor condenses on the heat exchange tube to heat the cold water inside the heat exchange tube, achieving the purpose of supplying hot water.

超低氮真空热水锅炉,采用意大利超低氮及冷凝换热技术,三回程湿背式燃烧室,大开启双向旋转式炉门,真空相变换热,内置一体式冷凝换热器。锅炉使用寿命长,热效率高,可满足采暖、卫生热水的供热需求。

The ultra-low nitrogen vacuum hot water boiler adopts Italian ultra-low nitrogen and condensation heat exchange technology, a three return wet back combustion chamber, a large opening bidirectional rotating furnace door, vacuum phase change heat exchange, and an integrated condensation heat exchanger. The boiler has a long service life, high thermal efficiency, and can meet the heating needs of heating and sanitary hot water.

配备品牌燃烧器,可加装烟气外循环装置(FGR),氮氧化物排放<30mg/m3,排放符合环保法规要求。

Equipped with branded burners, can be equipped with a flue gas external circulation device (FGR), with nitrogen oxide emissions less than 30mg/m3, and emissions in compliance with environmental regulations.

燃气真空热水锅炉的用途:

The purpose of gas vacuum hot water boiler:

供热采暖:商业综合体、酒店宾馆、办公楼、住宅、学校等。

Heating: Commercial complexes, hotels and guesthouses, office buildings, residential buildings, schools, etc.

生活热水:酒店、游泳馆、桑拿温泉、商业综合体、医院、学校、生产工艺用途等。

Domestic hot water: hotels, swimming pools, sauna hot springs, commercial complexes, hospitals, schools, production technology applications, etc.

燃气真空热水锅炉,出口天燃气丰富的中东和西亚国家(如俄罗斯,乌磁别克斯坦,伊郎,伊拉克,沙特阿拉伯,土耳其,印度,巴基斯坦)需要热水供热采暖的场所。

Gas fired vacuum hot water boilers are places where hot water heating is needed in Middle East and West Asia countries (such as Russia, Uzbekistan, Iran, Iraq, Saudi Arabia, Türkiye, India, Pakistan) exporting natural gas.

燃气真空热水锅炉性能参数 Performance parameters of gas vacuum hot water boiler | ||||||||||||

型号 model WZK-*** | ×104kcal/h | 30 | 60 | 90 | 120 | 180 | 240 | 300 | 360 | 480 | 600 | |

热功率Thermal power | kW | 350 | 700 | 1050 | 1400 | 2100 | 2800 | 3500 | 4200 | 5600 | 7000 | |

MW | 0.35 | 0.7 | 1.05 | 1.4 | 2.1 | 2.8 | 3.5 | 4.2 | 5.6 | 7.0 | ||

设计热效率Design thermal efficiency | % | 97~104 | ||||||||||

排烟温度Smoke exhaust temperature | ℃ | ≤(回水温度+10℃) | ||||||||||

电源source | V/Hz | 220~380/50(3N/50 220~380) | ||||||||||

用电总功率Total power consumption | kW | 1.1 | 2.5 | 4.2 | 5.5 | 9.5 | 11 | 15 | 18 | 24 | 27 | |

天然气natural gas | 最低耗量Minimum consumption | Nm3/h | 34.3 | 68.5 | 102.8 | 136.2 | 203.8 | 271.4 | 338.9 | 406.7 | 542.2 | 677.2 |

阀组口径Valve group diameter | DN | 32 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 80 | 80 | |

压力(动压) Pressure (dynamic pressure) | kPa | 5~7 | 6~8 | 6~8 | 8~10 | 10~12 | 12~15 | 14~16 | 14~16 | 16~18 | 16~18 | |

氮氧化合物(NOx)Nitrogen oxides (NOx) | mg/Nm³ | 80(BLUE)/ 30(FGR) | ||||||||||

锅炉安全阀口 Boiler safety valve port N3 | DN | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 80 | 80 | 80 | |

锅炉排汽口 Boiler exhaust port N4 | DN | 40 | 40 | 40 | 40 | 40 | 65 | 65 | 65 | 65 | 65 | |

锅炉排污口 Boiler discharge outlet N5 | DN | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

锅炉排烟口 Boiler exhaust port N9 | φmm | 219 | 273 | 325 | 377 | 426 | 500 | 560 | 600 | 700 | 800 | |

锅炉净重Net weight of boiler | t | 2.6 | 3.4 | 4.0 | 4.8 | 7.0 | 7.6 | 8.7 | 12.0 | 15.2 | 17.5 | |

热媒水容量Heat medium water capacity | t | 1.9 | 2.1 | 2.6 | 4.4 | 4.7 | 4.9 | 4.7 | 9.5 | 12.3 | 13.3 | |

运行重量Operating weight | t | 4.5 | 5.5 | 8.6 | 9.2 | 11.7 | 12.5 | 13.4 | 21.5 | 27.5 | 30.8 | |

A型换热器(△t=10℃,进/出水温度40℃/50℃、50℃/60℃,适用于地暖、中央空调采暖系统) | ||||||||||||

热功率Thermal power | ×104kcal/h | 30 | 60 | 90 | 120 | 180 | 240 | 300 | 360 | 480 | 600 | |

额定循环量Rated cycle capacity | m3/h | 30 | 60 | 90 | 120 | 180 | 240 | 300 | 360 | 480 | 600 | |

供水口N1/回水口N2 Supply port N1/Return port N2 | DN | 80 | 100 | 125 | 150 | 200 | 250 | 250 | 300 | 300 | 350 | |

B型换热器(△t=20℃,进/出水温度40℃/60℃、60℃/80℃适用于卫生热水、暖气片采暖系统) | ||||||||||||

热功率Thermal power | ×104kcal/h | 30 | 60 | 90 | 120 | 180 | 240 | 300 | 360 | 480 | 600 | |

额定循环量Rated cycle capacity | m3/h | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 | |

供水口N1/回水口N2Supply port N1/Return port N2 | DN | 50 | 80 | 80 | 100 | 125 | 150 | 200 | 200 | 250 | 250 | |

备注: 1、燃料计算基准值:天然气低位发热值8500kcal/Nm3; 2、排烟温度随回水温度的变化而变化,排烟温度≤(回水温度+10℃); Note: 1. Fuel calculation benchmark value: natural gas low heating value 8500kcal/Nm3; 2. The exhaust temperature changes with the temperature of the return water, and the exhaust temperature is ≤ (return water temperature+10 ℃); In the process of continuous innovation and improvement, the above parameters may change, and the final drawing shall prevail. | ||||||||||||

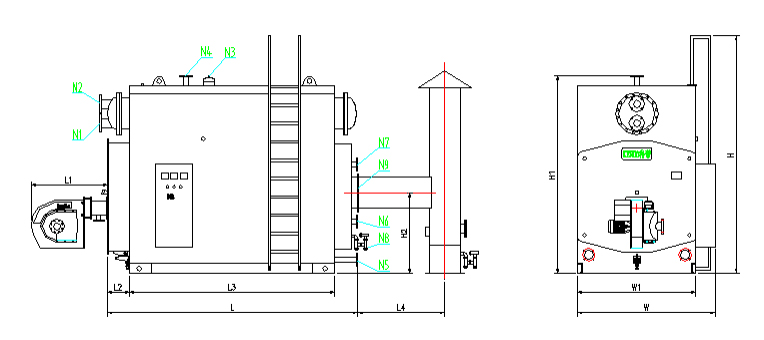

WZK型低氮(NOX<30-50mg/m3)冷凝真空热水锅炉外形尺寸-示意图

Outline dimensions of WZK low nitrogen (NOX<30-50mg/m3) condensing vacuum

hot water boiler - schematic diagram

WZK型低氮(NOX<30-50mg/m3)冷凝真空热水锅炉外形尺寸数据-参考示意表

Outline Dimensional Data of WZK Low Nitrogen (NOX<30-50mg/m3) Condensing Vacuum Hot Water Boiler - Reference Diagram Table

热功率Thermal power | L | L1 | L2 | L3 | L4 | W | W1 | H | H1 | H2 | |

×104kcal/h | kW | ||||||||||

30 | 350 | 2561 | 508 | 157 | 2130 | 1200 | 1554 | 1302 | 2614 | 2114 | 870 |

60 | 700 | 2947 | 840 | 157 | 2520 | 1200 | 1675 | 1422 | 2803 | 2326 | 920 |

90 | 1050 | 3240 | 840 | 157 | 2810 | 1200 | 1725 | 1472 | 2888 | 2417 | 960 |

120 | 1400 | 3662 | 863 | 157 | 3160 | 1200 | 1902 | 1672 | 3133 | 2641 | 1070 |

180 | 2100 | 3987 | 1178 | 157 | 3500 | 1200 | 2022 | 1772 | 3302 | 2826 | 1150 |

240 | 2800 | 4186 | 1178 | 157 | 3650 | 1200 | 2122 | 1872 | 3447 | 2971 | 1200 |

300 | 3500 | 4759 | 1178 | 187 | 4150 | 1500 | 2197 | 1972 | 4036 | 3161 | 1300 |

360 | 4200 | 5046 | 1178 | 187 | 4380 | 1500 | 2454 | 2176 | 4199 | 3394 | 1360 |

480 | 5600 | 6030 | 1325 | 187 | 5340 | 1500 | 2584 | 2276 | 4376 | 3627 | 1450 |

600 | 7000 | 6482 | 1637 | 187 | 5790 | 1500 | 2774 | 2476 | 4662 | 3788 | 1600 |

中国常州市上能锅炉有限公司联系方式

Contact information of Changzhou Shangneng Boiler Co., Ltd., China

联系人:芮亚平

Contact person: Rui Yaping

手机:+8613815029577

Mobile:+8613815029577

邮箱:czjnguolu@163.com

Email: czjnguolu@163.com

微信号:13815029577

WeChat ID: 13815029577

工厂地址:中国常州高新区黄河西路225号

Factory address: No. 225 Huanghe West Road, Changzhou High tech Zone, China

开户行:中国工商银行常州钟楼支行

Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch

美元帐号:1105020509714031781

USD account: 1105020509714031781